White-label shop for digital intelligent assistance and human-AI collaboration in manufacturing

THE PROJECT

WASABI focuses on digital intelligent assistance solutions, based on human-AI collaboration, and applied to the manufacturing domain. The WASABI solution increases the cognitive abilities of workers and accelerates the acquisition and transfer of knowledge, through Natural Language Processing (NLP) system, for the upskilling of the existing workforce, meantime securing job positions.

Our challenge is related to SMEs and mid-caps manufacturers in Europe that need to meet sustainability goals. Producing components for complex products, or often operating in emerging specialty equipment markets, they must be quite careful about spending their resources on activities with uncertain costs or outcomes.

Wasabi makes digital intelligence assistance and conversational artificial intelligence solutions become standard practices, accessible, affordable, and manageable even for small companies. Wasabi allows European SMEs to achieve sustainability principles and technological and operational innovation capacity, such as to become renewed and cutting-edge, and reach leadership goals and market competitiveness.

TECHNOLOGY

WASABI reuses and customizes technologies from previous projects. The rEUse waste management digital platform, to manage circular economy information about circular entities, processes and services (SYXIS), that covers production and recycling, and COALA (BIBA, ICCS, and SYXIS), a human-centred AI-based digital assistant, focused on education and training, that covers production and product end-of-line testing. WASABI positions its business cases along the product life cycle to demonstrate its solution’s coverage and adaptability.

The three initial cases represent typical problems in manufacturing. The first business case concerns the valorisation of production waste. The second business case concerns the fast and cost-efficient onboarding of new factory workers. It combines knowledge management and learning theories with digital assistant technology. The third business case focuses on improving manufacturing quality. It covers, for instance, product tests and end-of-line quality control procedures and applies digital assistant technology in combination with prescriptive quality analytics.

TECHNOLOGY

WASABI reuses and customises technologies from previous projects. The rEUse waste management digital platform, to manage circular economy information about circular entities, processes and services (SYXIS), that covers production and recycling, and COALA (BIBA, ICCS, and SYXIS), a human-centred AI-based digital assistant, focused on education and training, that covers production and product end-of-line testing. WASABI positions its business cases along the product life cycle to demonstrate the coverage and adaptability of its solution.

The three initial cases represent typical problems in manufacturing. The first business case concerns the valorisation of production waste. The second business case concerns the fast and cost-efficient onboarding of new factory workers. It combines knowledge management and learning theories with digital assistant technology. The third business case focuses on improving manufacturing quality. It covers, for instance, product tests and end-of-line quality control procedures and applies digital assistant technology in combination with prescriptive quality analytics.

GOALS

01

Sustainability

Aims at minimising the number of sustainability incidents in manufacturing, through the implementation of DIA (Digital Intelligent Assistant) solutions. It focuses on waste valorisation and product quality test procedures optimisation, to save energy and materials.

02

Agility & Resilience

Aims at reducing the training time for workers in manufacturing. It focuses on assisted workforce management to shorten the onboarding of new workers, and to optimise the upskill of other roles, providing a training concept and materials for human-AI collaboration.

03

Technology Adoption

Aims at increasing the uptake of intelligent digital assistance technology, to augment workers’ cognitive capabilities, assist them during difficult tasks, guiding them through knowledge-intensive procedures where lapses could result in injury, and allowing them to delegate the simpler activities.

04

Innovation capacity

Aims at making digital assistance technologies and related services available to innovation infrastructures. It focuses on providing an overview about Europe’s legal framework regarding AI related contract law and the emerging trustworthy AI legislation, increasing innovation capacity, agility and productivity of the manufacturing sector, in particular for SMEs and mid-caps.

05

Leadership

Aims at overcoming barriers and scepticism about intelligent digital assistance in industry. It focuses on increasing competitiveness through customised e-commerce software with federation capabilities and a cloud and edge deployment for DIA infrastructure, contributing to standardization on conversational AI and interoperability.

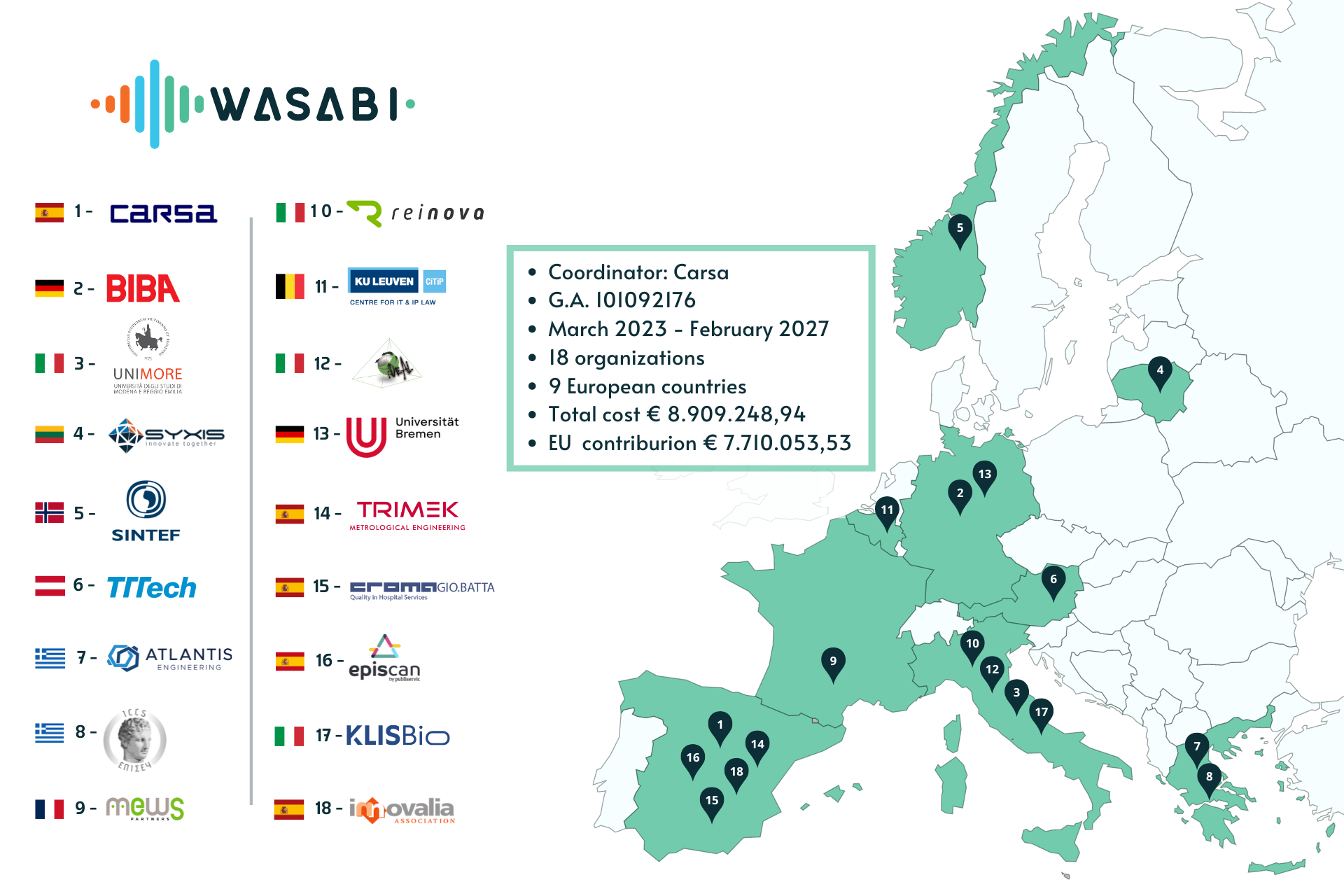

OUR NUMBERS

A strong consortium has been built to cover all aspects of technical, industrial, and business requirements, going from industry to academia, to provide a complete value chain to bring new products and services to the manufacturing market.